loading..

loading..

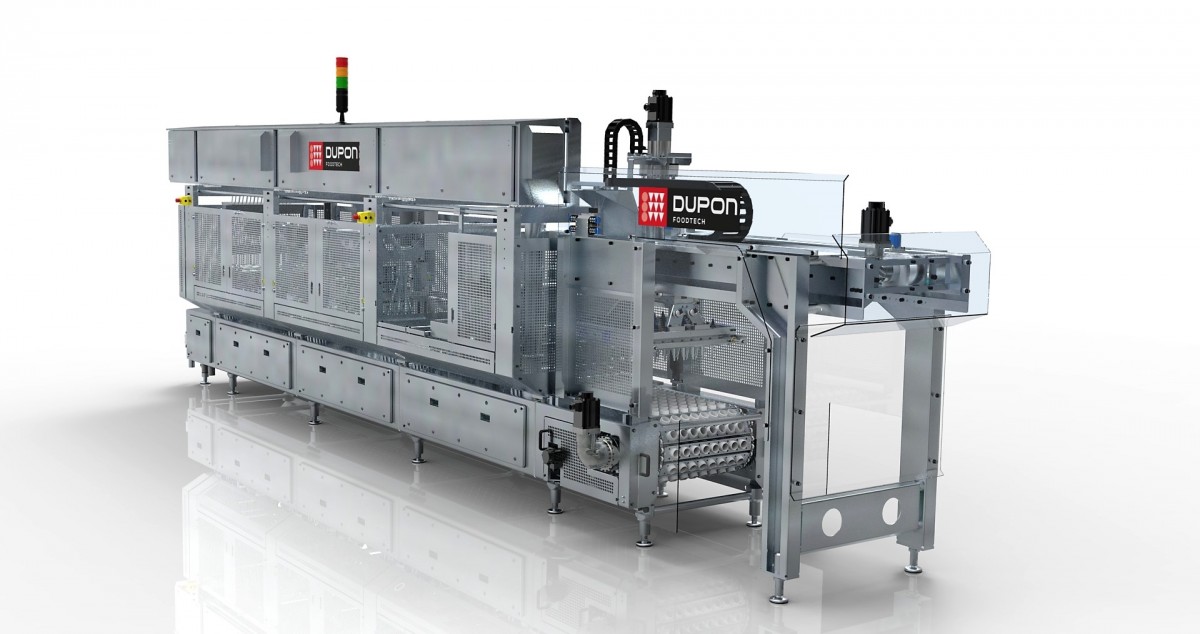

Dupon Foodtech has been designing and manufacturing cone filling lines for over many years.

Today the Dupon foodtech brand is acknowledged worldwide for its innovation & performance in the market.

Our engineering division is offering to the ice cream industry any type of filling and decoration

of cones, cups, tubes, push ups, squeeze ups or individual portions of ice cream or sorbet.

Output capacity: from 2000 pcs/hour up to 43200 pcs/hour, rotary or inline conception layout, open & close valves,

extrusion valves, volumetric valves and fruit valves, multinozzles valve, tartuflo inside core filling, mechanical movements or servo-driven,

pencil devices, ripples, syrup dosers, volumetric or vibration dry topping dispensers, cocoa powder dispensers (tiramissu)

All what our customers like, our engineers will design & conceive.

Contact us and define your ice cream. We will help you to make it appealing to your customers.

The Dupon Foodtech plate hardening tunnels are designed & built state of the art.

Robot loading system to plates or baskets, easy plate change, stainless steel transport chain and floor (walls if requested),

inter-cooler evaporators in stainless steel (frame & pipes), ammonia, carbon dioxide R-744 or freon refrigerants,

defrosting system by hot gas, oil free chain system or lubricated chain (automatic lubrication).

We use the best isolating pannels and most reliable inter-cooler evapurators in the market.

Freezing capacity: for 120 ml cones - 28800 pcs/hour, 36000 pcs/hour or 43200 pcs/hour.

Call us and we will design the tunnel to fit in the available hall space you have.

With Dupon Foodtech you can also be entitled to the following services: